Product quality control in the production process is to ensure that the production process is in a controlled state, and to analyze, diagnose and monitor the operation technology and production process adopted in the production, installation and service processes that directly or indirectly affect product quality. It is usually ensured by the following measures:

Equipment control and maintenance

Make corresponding provisions on equipment tools, measuring instruments, etc. that affect product quality characteristics, and verify their accuracy before use, and store and maintain them reasonably between two uses. Protection, and regular verification and recalibration; formulate preventive equipment maintenance plans to ensure the accuracy and production capacity of the equipment to ensure continuous process capability;

Material control

The type, number and requirements of materials and parts required in the production process Make corresponding provisions to ensure that the quality of process materials are qualified, and maintain the applicability and fitness of the products in the process; state the materials in the process to ensure the traceability of the material identification and verification status;

Documents are valid

Ensure that the operating instructions and quality inspection versions of each product are correct;

First inspection

The trial production process is indispensable, and the molds, checking fixtures, fixtures, workbenches, machinery and equipment are properly matched through trial production. And the installation is correct, it is very necessary to carry out mass production after the trial production offline products are confirmed to be qualified, and the trial production offline products cannot be mixed into the official products!

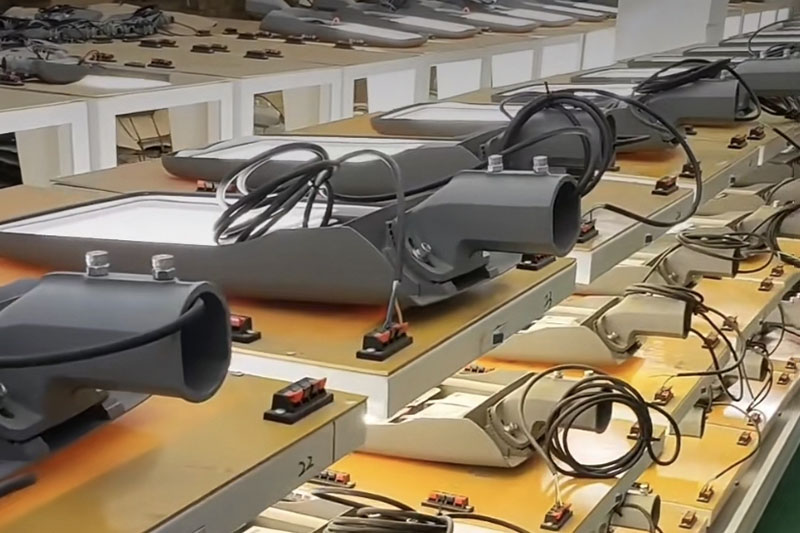

Patrol inspection

Conduct patrol inspections on key processes during the production process, and sample inspections according to quality inspection requirements to ensure that the parameters in the process maintain a normal distribution. If there is a deviation from the hard shutdown, continue production and increase inspection efforts;

Quality inspection status control

Mark the inspection status of the finished product in the process (outsourcing), distinguish unverified, qualified or unqualified products through the mark (certificate), and pass the mark to identify and verify the responsibility;

Isolation of non-conforming products

Formulate and implement non-conforming product control procedures, find non-conforming products in time, clearly identify and store non-conforming products, and supervise the treatment methods of non-conforming products to prevent customers from receiving non-conforming products Unexpected use of unqualified products and non-conforming products to avoid unnecessary costs incurred by further processing substandard products.